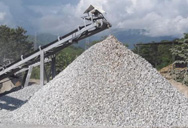

grinding asphalt or concrete surfaces

What Are Asphalt Grindings and How To Use

2023.2.28 Asphalt grindings can be used in a variety of ways, such as paving new surfaces, filling potholes, and as a base for new construction projects. Asphalt is a durable material that can withstand heavy traffic

اObtener precio

Concrete Grinding: The Comprehensive Guide to Perfect Surfaces

2023.8.24 But what exactly does it entail? Let’s take a look into the world of grinding, its advantages, and the tools that make it all possible. What Exactly is Concrete

اObtener precio

Texturing and evaluation of concrete pavement surface: A

2023.9.1 The ISAC team has also investigated the polishing resistance of four different concrete pavement surfaces using the APM test (Lu et al., 2021). The selected

اObtener precio

Appendix B Pavement Rehabilitation Techniques

Asphalt concrete can be removed to a depth of a foot or more in a single pass. Cold milling may be done for one or more of several reasons: To texturize the surface prior to

اObtener precio

Surface texture and friction characteristics of diamond-ground concrete ...

2016.10.1 Compared to other pavement preservation treatments such as overlays and high friction surface treatments, diamond grinding may cost less, save construction

اObtener precio

Surface Preparation – Pavement Interactive

Surface preparation generally takes one of two forms: Preparing the subgrade and granular base course for new pavement. This can involve such activities as subgrade stabilization, over-excavation of poor

اObtener precio

Existing Surface Preparation for Overlays –

Repair Generally, pavement overlays are used to restore surface course (both HMA and PCC) characteristics (such as smoothness, friction and aesthetics) or add structural support to an existing pavement. However,

اObtener precio

Negative texture, positive for the environment: effects of

The latter is exclusively used on cement concrete pavements, while our horizontal grinding has been used only on asphalt pavements (but can equally well be used on concrete).

اObtener precio

(PDF) Negative texture, positive for the

2019.4.25 Negative textures are typical of porous asphalt pavements, but another way to achieve this feature is to grind off the peaks of the surface. This paper explores the effects of grinding off...

اObtener precio

Concrete Grinding [A Complete Guide] BW

Concrete grinding is a concrete pavement preservation method that can remove unevenness, irregularities, and even some forms of damage from an area of concrete.

اObtener precio

Information Summary Asphalt Grindings / RAP (Recycled

2013.6.21 concrete surfaces. Asphalt grindings contain approximately five to seven percent asphalt, which is used as a binder for the quarry materials (stone, rock, sand, silt) that make up the load-bearing portion of a bituminous concrete surface. The asphalt millings are produced by grinding a bituminous concrete-paved surface.

اObtener precio

Recommended Construction Guidelines For Standard

2018.4.1 Asphalt Recycling Reclaiming Association 800 Roosevelt Road, Building C-312 Glen Ellyn, IL 60137 (630) 942-6578 ARRA . 12/22/2016 CP101-1 1. General Cold Planing (CP) consists of milling a portion of the existing asphalt or concrete pavement to the length, depth, and width shown on the plans to remove wheel ruts and

اObtener precio

Trench grinder for cutting and grinding asphalt or concrete

A trench grinder (10) which may be mounted on a mobile carrier (16) via arms (12) which permit raising and lowering of the grinder (10). The grinder (10) comprises a drum equipped with picks to cut asphalt, concrete, or the like from the surface of a road or the like. The grinder (10) can be moved laterally by a chain drive mounted on a plate at the end of the

اObtener precio

Appendix B Pavement Rehabilitation Techniques

Asphalt concrete can be removed to a depth of a foot or more in a single pass. Cold milling may be done for one or more of several reasons: To texturize the surface prior to resurfacing in order to enhance bond, To remove excess asphalt concrete thickness, to remove oxidation at the surface, To remove unstable or deteriorated asphalt concrete ...

اObtener precio

What Is Diamond Grinding Concrete? - Stockxbeats

2022.5.3 Concrete grinding is used to smooth rough concrete surfaces. An abrasive tool is used during the concrete grinding process to smooth the rough surface. ... Can a concrete grinder be used on asphalt? Diamonds are used to remove roadway imperfections caused by construction and heavy usage. An improvement in pavement smoothness,

اObtener precio

asphalt diamond grinding

2023.8.10 it can be performed on new or existing pavement. Commonly used on concrete for over 60 years, diamond grinding is increasingly used on asphalt as well. Numerous states have used it to improve their roads’ smoothness and friction characteristics, while creating a quieter ride. Road Owners increasingly see benefits

اObtener precio

Advantages of Diamond Grinding Concrete Pavement

2017.4.18 The project included 13,000 square yards of roadway and dock pavement over a 1,800-foot long section of the warehouse. The pavement had an asphalt overlay installed several years ago, which was showing signs of distress with large areas of delamination and reflective cracking. Diamond grinding process improves the surface

اObtener precio

IGGA Guide Specification Conventional Diamond

2018.12.18 Conventional Diamond Grinding for Pavement Preservation Publication Date: 9-30-14 (Rev 5/19/15) SCOPE This standard specifies the procedures for operations of continuous diamond grinding Portland cement concrete or asphalt concrete pavement and roadway surfaces to provide desired surface characteristics such as ride, friction and

اObtener precio

Negative texture, positive for the environment: effects of

An early pilot trial to create a “negative texture” for noise reduction was carried out in 2006 by Sandberg and Ejsmont (Sandberg, Citation 2007) in cooperation with the company manufacturing the grinding machines, by grinding off the top 1 mm of a dense asphalt concrete pavement with maximum 11 mm aggregate (DAC11) on a 40 m long strip in ...

اObtener precio

Asphalt Overlays: Preparation and Application By: Jacob

2020.2.3 The diamond grinding can only be used on hot mix asphalt to reduce raised areas and level them to the road, but in concrete can be used to take ... Freeze thaw cycles take a toll on asphalt surfaces in that the expanding and ... used type of tack coat materials are hot asphalt cement, emulsified asphalt and cutback asphalt (IDOT, 2012). ...

اObtener precio

Scarifying vs. Grinding Concrete - Onfloor

2021.10.20 It slices into asphalt or concrete surfaces and removes loose material from cracks, joints, and other parts of the surface. As part of the surface prep process, this also makes it easier for the sealer to attach itself to those areas once applied, which helps form a protective layer on top of the broken area - preventing water infiltration over ...

اObtener precio

Diamond Grinding Asphalt Pavement for Improved

2020.7.7 Diamond Grinding Asphalt Pavement Indianapolis Motor Speedway Diamond ground asphalt surface Asphalt pavement can be ground and grooved just like concrete pavement. Diamond Ground Asphalt Surface. What is Diamond Grinding? Removal of thin surface layer of pavement surface using closely spaced diamond saw blades

اObtener precio

Noise emission of concrete pavement surfaces produced by diamond grinding

2015.4.1 However, up to now it is not known which textures produced by grinding are particularly suitable for noise reduction. The effect of various parameters on the textural properties of concrete pavement surfaces produced by grinding and the resulting noise levels have been studied in a research project (Villaret et al., 2013). The research project ...

اObtener precio

7 Different Types of Asphalt: Everything You Need to Know

2023.1.9 1. Hot Mix Asphalt (HMA) Hot asphalt, also known as hot mix asphalt (HMA), is the most used type of asphalt. It is made by heating a mixture of aggregate (crushed stone, gravel, and sand) and asphalt cement (a petroleum product) at a high temperature, usually around 300-350 degrees Fahrenheit.

اObtener precio

Concrete chipping machine: an attachment to the grinding machine

2019.10.3 Concrete chipping is a mechanical process practiced in the construction industry in order to increase adherence to smooth surfaces. It is carried-out before plastering of beams, columns and other concrete structures with smooth surfaces. The objective of this project was to design a low-cost concrete chipping machine suitable for the construction

اObtener precio

What is Asphalt Milling? Process and Benefits

2021.5.21 The short answer is that asphalt milling is the process of partial or full removal of asphalt surface. Most of the removed material can then be process to become recycled asphalt. Asphalt first began to be repurposed as interstate or airplane tarmac lost its usefulness. One can obtain recycled asphalt after initial asphalt product is removed ...

اObtener precio

Thermoplastic Application Guide (How To) Transline

Rapidly turn over material. Pavement and air temperatures should be above 50F. Apply primer (where recommended) and thermoplastic at correct thickness. Residual primer solvent must evaporate prior to thermoplastic application. Do not overheat material. Verify material temperatures calibrate kettle thermometers.

اObtener precio

Asphalt Surfacing of Concrete 105 Bridge Decks - VicRoads

2016.12.29 During placement, the asphalt layer will cool extremely quickly because concrete bridge decks are good heat conductors. It is therefore very important to have the rollers working closely behind the asphalt paver. Where an asphalt wearing course is placed over a regulation layer of asphalt, a tack coat between these layers is required.

اObtener precio

What’s Under Foot? - Rails-to-Trails Conservancy

Grind – Rebound Ace Prepare subbase, place geotextile, 6” aggregate base, pour concrete or asphalt base, apply rebound Ace surface directly over hard surface. 8-12 years Replace topcoat after 10 years No B, P, W, S, but not tested, intended application is sport surfaces Yes Yes L C, A, G $10.50 $2,686,320 Permeable Concrete

اObtener precio>> Next: Trituradora De Cono Para áridos

Mas noticias

- used mining equipment for quartz mica feldspar in the uk

- separacion por gravedad de los minerales de manganeso

- proceso de manganeso mineria

- planta de trituración usada en venta cenit

- varilla utilizada y molinos de bolas para la molienda de mineral

- equipo de tintoreria en venta

- planta de trituración en indonisia y trituradora de piedra precio mini

- planta modular de oro a pequea escala

- trituradoras de piedras mas grandes del mundo

- piedras de moler en quetzaltenango

- maquinas trituradoras de piedra en colombia

- densidad de la grava triturada 6 tamano

- de las trituradoras de mandibula en operaciòn

- molino de tres rodillos marca

- dimensiones de un molino tipo marcy

- tire hacia atrás la varilla trituradora de mandíbula de primavera

- pequeña mina de cobre y todavía

- deja molino para preparar alimentos para animales

- resumen de molino de barras y bolas

- cuantos tipos de energia hay y cuales son

- efectos secundarios de la piedra china que estimula

- paginas de españa venta de molinos de segunda mano

- Equipos Chancadoras De Piedras

- Crystal Quarry Underground Map Rohan Where Is Kaildarr The Magic Armor

- venta caliente de la serie mandíbula móvil de trituración de la planta

- salvavidas pescante botes

- trituradora de piedra de 18 × 10

- pengertian data mining dan teks mining

- quarry distribuidores de equipos de la planta en argelia

- oaxaca trituradora en