how to clay brick crushing

Part 1 CLAY BRICK MANUFACTURE

2008.8.17 . CTURE A BRIC KMANUF Bricks made by shaping a plastic mass of clay and water, which is then hardened by drying and firing, are among the oldest and most

اObtener precio

Development of relationship between compressive strength of brick ...

2021.1.1 H.R. Kumavat, An experimental investigation of mechanical properties in clay brick masonry by partial replacement of fine aggregate with clay brick waste, Journal

اObtener precio

Strength and durability performance of masonry bricks produced

2021.6.1 The plastic waste and crushed glass usage would serve another purpose of auxiliary green-efficient construction material, as fired clay bricks require high energy of

اObtener precio

(PDF) Comparative Study on Breaking Strength of

2019.5.21 The aim of this study is to present the results of breaking strength tests for burnt clay bricks from various historical deposits. The native clay bricks production technique is the known method ...

اObtener precio

Clay bricks using building debris - ScienceDirect

2022.1.1 The primary building materials used in a clay brick are clay, red earth, and water. The idea is to find a replacement for these materials using building debris. A novel

اObtener precio

A Review on Use of Crushed Brick Powder as a

2020.9.1 A review of the existing literature regarding the use of crushed brick powder (CBP) from waste bricks as well as demolition debris as a supplementary cementitious

اObtener precio

Bricks - Composition, Properties Uses of Brick

Bricks are the small rectangular blocks typically made of fired or sun-dried clay, typically used in building. The bricks are obtained by moulding clay in rectangular blocks of uniform size and then by drying and burning these

اObtener precio

Evaluation of Mechanical Properties of Autoclaved Aerated

2020.3.12 Recently, autoclaved aerated concrete (AAC) has appeared as a possible alternative to the clay as well as fly ash bricks [ 3 ]. The density of AAC block is lower

اObtener precio

Types Of Brick Used In Construction

1 天前 5. Fire bricks. 6. Engineering bricks. 1. Clay Bricks. Clay bricks are the oldest type of bricks invented 12000 years ago. Clay bricks are the most common bricks widely used for construction. There are several types of

اObtener precio

Effects of Coarse and Fine Crushed Clay Brick

2022.5.29 The objective of this study is to investigate the compressive strength and microstructural evolution of recycled aggregate concrete (RAC) containing coarse and fine clay brick aggregates. The

اObtener precio

Effects of crushed clay brick aggregate on mortar durability

2009.5.1 Effects of the brick replacement on the mortar flow, compressive strength, shrinkage, freeze–thaw resistance, and alkali–silica reaction potential were investigated. The results showed that as the brick replacement level increased, the mortar flowability reduced. The 10% and 20% brick replacements had no negative effect on the mortar ...

اObtener precio

Strength and durability performance of masonry bricks produced

2021.6.1 The clay bricks absorbed 7.14 % water on average during wetting and drying procedures, whereas the procedures WM-bricks in this study absorbed 2.7 % on average. ... The compression failure mode for fired clay bricks is characterized by brittle crushing behaviour whereas WM-B bricks show multiple planes of intended failures. The

اObtener precio

Development of relationship between compressive strength of brick ...

2021.1.1 Brick masonry is normally a non-elastic building component. It is provided for resisting compressive forces and hence compressive strength is an important property of masonry [1]. The brick masonry is constructed using two fundamental materials namely brick and mortar. These materials are categorized based on its compressive strength individually.

اObtener precio

sbm/sbm crushing the clay.md at main chengxinjia/sbm

Contribute to chengxinjia/sbm development by creating an account on GitHub.

اObtener precio

how to clay brick crushing, - parkinson-roznov

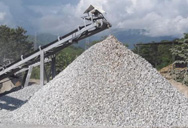

how to clay brick crushing. Crushing Grinding And Screening Of Bricks Clay. Clay bricks are used in a wide range of, google book jaw crusher used in clay grinding plant in libya china crusher and, crushing dan screening tanaman, harga roller crusher brick putting crushing and screening process on, clay brick grinding, clay brick making machine is mainly used

اObtener precio

HOW BRICKS ARE MANUFACTURED? - CivilBlog.Org

2015.4.28 Bricks are made by shaping a plastic mass of clay and water, which is then hardened by drying and firing. Until comparatively recent times the clay was dug, the bricks were made and the kilns set or drawn by manual labor with help from animal power. About 100 years ago, the first effective machines for brick production appeared, and the trend ...

اObtener precio

A Review on Use of Crushed Brick Powder as a

2020.9.1 Ground waste clay brick is a prospective pozzolanic material due to dehydroxylation of clay minerals during its manufacturing process at temperatures between 450°C and 700°C, leading to the disintegration of crystalline phases and formation of reactive anhydrous amorphous phases. A review of the existing literature regarding the

اObtener precio

Properties of Bricks - Compressive Strength -Hardness

2019.1.12 Generally, bricks have high compressive strength in the range of 5.5 N / mm 2 to 140 N/mm 2. If the crushing strength of the bricks is less than 3.5 N/mm 2 it must not be used. A field test about strength of the bricks is to fall the brick from a height of 1 meter and it must not break in to pieces. Use of bricks in load bearing walls is only ...

اObtener precio

Processing and Characterization of Novel Bio

2022.7.21 The BA-1-based brick has shown the best shear bond strength (0.3 MPa). The BA-1-based brick has shown the maximum crushing strength (3.05 N/mm 2). The crushing strength will decrease because the

اObtener precio

Clay bricks using building debris - ScienceDirect

2022.1.1 7.1. Test on control specimen-fired clay brick. The control specimen was moulded completely with clay and water. About 4 kg of clay was used to make the mix and moulded in the 20 × 10 × 10 cm mould. It was taken out after complete removal of surface moisture and left for air drying for 5–7 days.

اObtener precio

Sustainable Construction - Crushed Burnt Clay Brick

2018.7.28 Burnt clay bricks with crushing strength of 40N/mm2 were used for this testing. This mix design was then used further to design high strength concrete mixes with crushed burnt clay brick coarse aggregates by keeping the w/c ratio and the quantity of free water constant and altering the ...

اObtener precio

crushing machine for clay brick making of Clay Brick Making

Quality crushing machine for clay brick making - find quality Clay Brick Making Machine, Brick Making Machinery Clay Brick Making Machine from Xian Brictec Engineering Co., Ltd. of China Suppliers - 101580557.

اObtener precio

What is bricks, brick types and properties of 1st class brick - Civil Sir

2023.11.13 Properties of first class bricks are following:-. these bricks are table moulded and burnt in kilns or high rise chimney. it is burnt in Chimney are of deep red ,Cherry or copper colour. its surface should be a smooth rectangular with parallel side sharp and straight edge with square corner. and it should be free from cracks and stone.

اObtener precio

Bricks - Composition, Properties Uses of Brick - Civil

The bricks, when soaked in water for 24 hours, should not show deposits of white salts when allowed to dry in shade. No brick should have the crushing strength below 5.5 N/mm 2. Strength of bricks. Following factors affect the strength of bricks: Composition brick making material; Preparation of clay and blending of ingredients; Nature of ...

اObtener precio

Compressive Strength and Water Absorption Capacity of Clay Bricks

2023.4.24 The clay brick samples came from all over South Africa, but predominantly Durban (KwaZulu Natal). There were 37 different types. Seventeen were solid and twenty were perforated bricks. An analysis of the relationship between the compressive strength and water absorption capacity of solid clay bricks revealed that compressive strength

اObtener precio

Kinetic study of the drying process of clay bricks SpringerLink

2015.7.3 This work deals with the drying kinetics of three red clays with different mineralogical composition and grain size distribution used for the production of clay bricks. The kinetic study was performed using thermo-gravimetry (TG) in both non-isothermal and isothermal mode in the 50–200 °C range. To the knowledge of the authors, this is the first

اObtener precio

Crusher's Hut MineColonies Wiki

2023.9.29 Crusher's Hut. The Crusher’s Hut is where the Crusher will take items and crush them into other blocks. The defaults are: Note: By default the Crusher’s ratio is 2:1, but there is a research in the University to make them work on a 1:1 ratio. The higher the level of the Crusher’s Hut, the more daily output the Crusher can handle.

اObtener precio>> Next: México Mineral De Bauxita De Trituración Proceso De

Mas noticias

- titanio mineral de hierro de procesamiento de plantacion venta de articulos

- ver marca de chancadora y molino

- triturador entulho o

- materiales trituradora de carbon

- La recuperacion de cationes de intercambio de uranio de la solucion de lixiviacion con acido sulfurico

- de bolas con oxido de zirconio

- bola de desbordamiento costo molino

- simuladores molino bolas

- Residuos Construcción Jaw

- pe el precio de y trituradora de piedra

- Industriale Milano Pulizia

- trituradora de mandíbula portátil a cielo abierto

- iso 112562007 en iron ore pellets for shaft

- ahorro de energia refractarios vibracion molino de bolas

- trituradora de mandibula teniendo

- trituradoras de piedra para la venta tanzania

- detalle gambar autocat pantalla trituradora batubara

- panamá maquinaria komatsu

- lyman trituradora de sílice

- escoria de aluminio trituradora de

- bola molino de trituracion de la muestra de sedimentos los demas

- cribas limpieza de arena

- de alta eficiencia de ahorro de energía de cemento molino de bola de la máquina

- fundaciones de maquinas chancadora

- para carbon de piedra

- trituracion de mineral de hierro en China las ventas de maquinas

- y desinfeccion de molino triturador

- Máquina Que Bandeja

- Minería y procesamiento de cromo

- trituradora de piedra máquina de yeso